Mirroring Reality, Transforming Industries

Experience ProcessHub

ProcessHub

OPERATIONAL EXCELLENCE

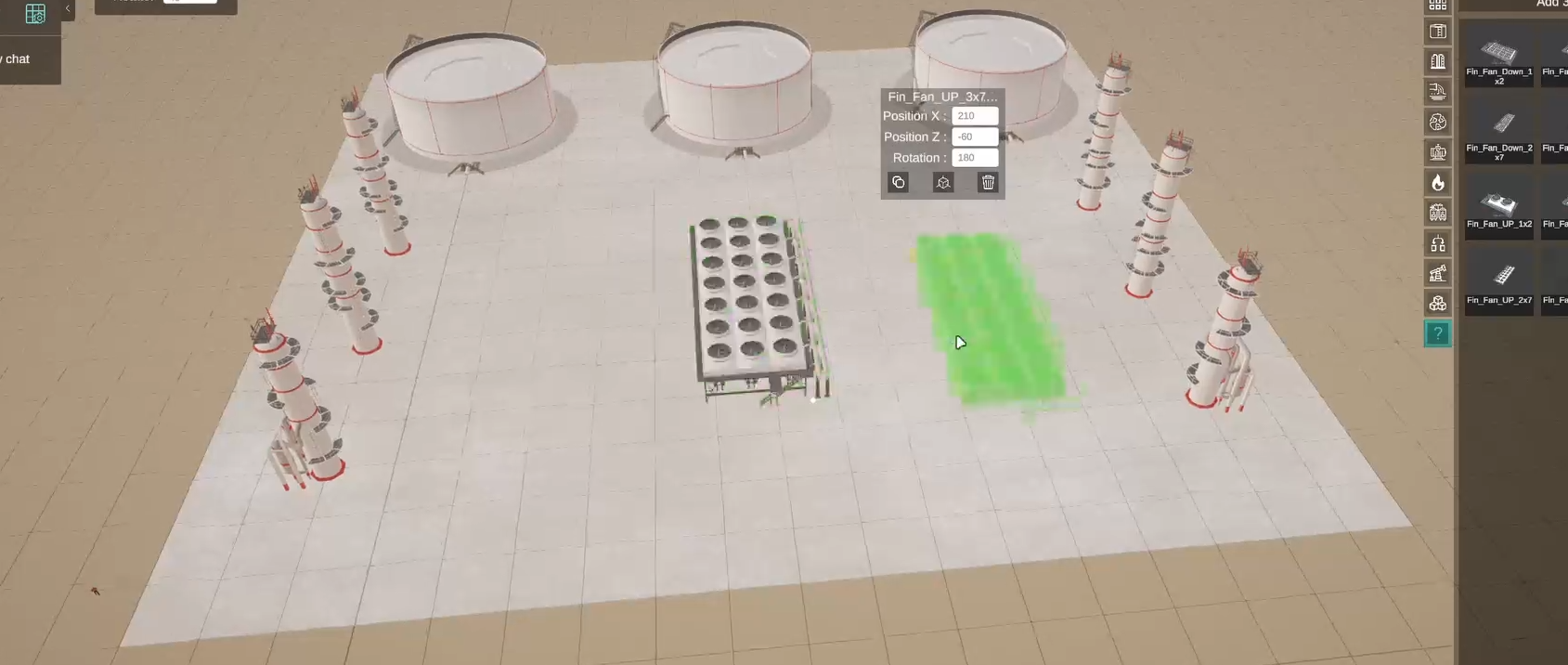

Enhances asset management by transforming operational data into a real-time Digital Twin. By integrating with IoT, SCADA, and other enterprise systems, it provides continuous monitoring, predictive analytics, and process optimization to ensure peak performance across facilities. Users can either leverage a digital twin generated through Progress Monitoring or build their own using integarted 3D assets library. The system enables real-time asset tracking, automated risk detection, and resource optimization, giving stakeholders full visibility and control over operations. With seamless integration into existing infrastructure, Operational Excellence helps minimize downtime, reduce costs, and improve efficiency—whether for industrial facilities, utilities, or large-scale infrastructure projects.

Build Digital Twin

Dashboard for Actionable Intelligence

AI & ML for Predictive Maintenance

Predictive Asset Monitoring

Historical Data & Analytics

Build 3D digital twin of the plant using asset library or custom models.

Create Unit/Asset/Equipment hierarchy for structuring data.

Integrate to existing IT network inside the plant/factory to fetch the data.

Set up alarms and operational ranges. Use it while AI will analyze data and give you insights.

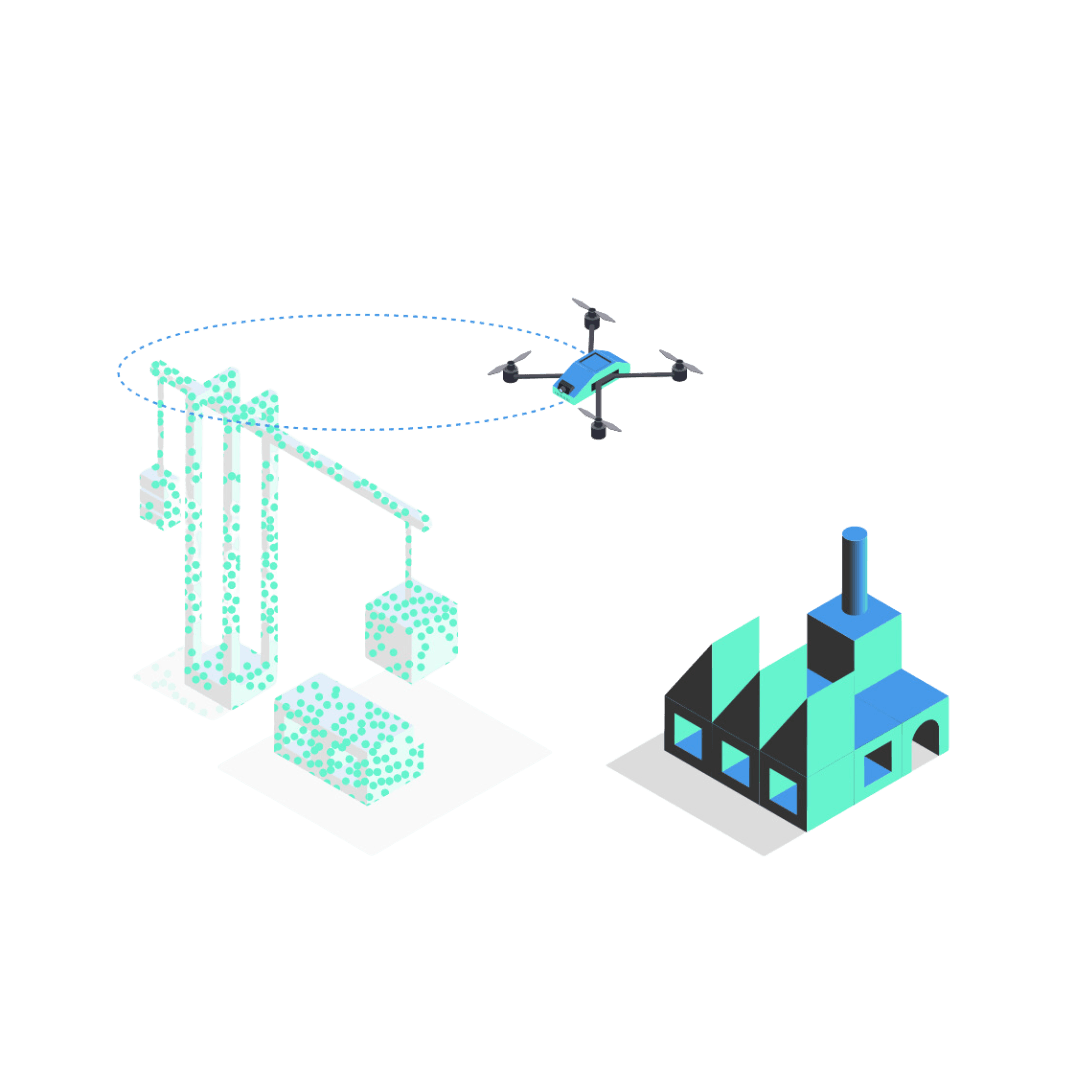

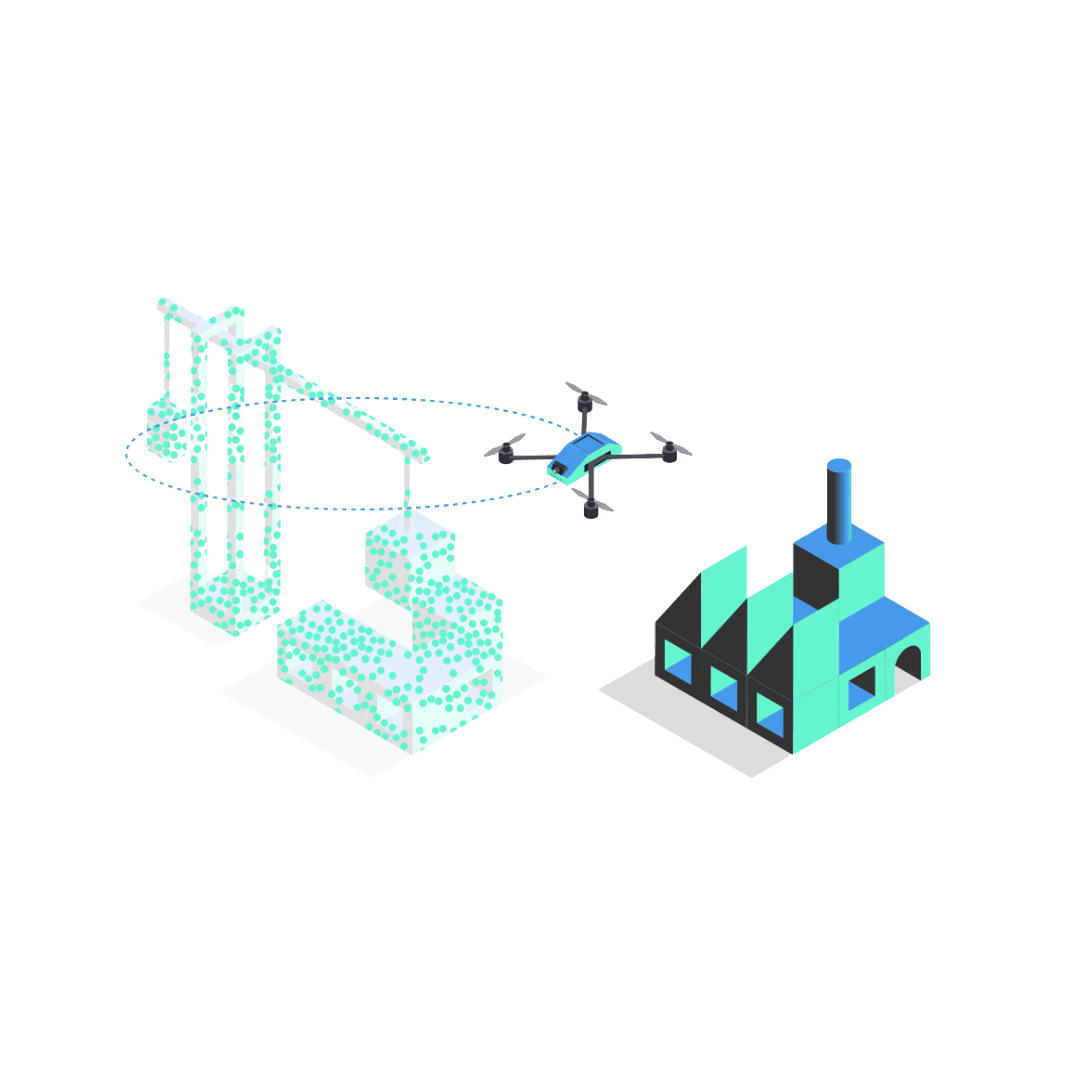

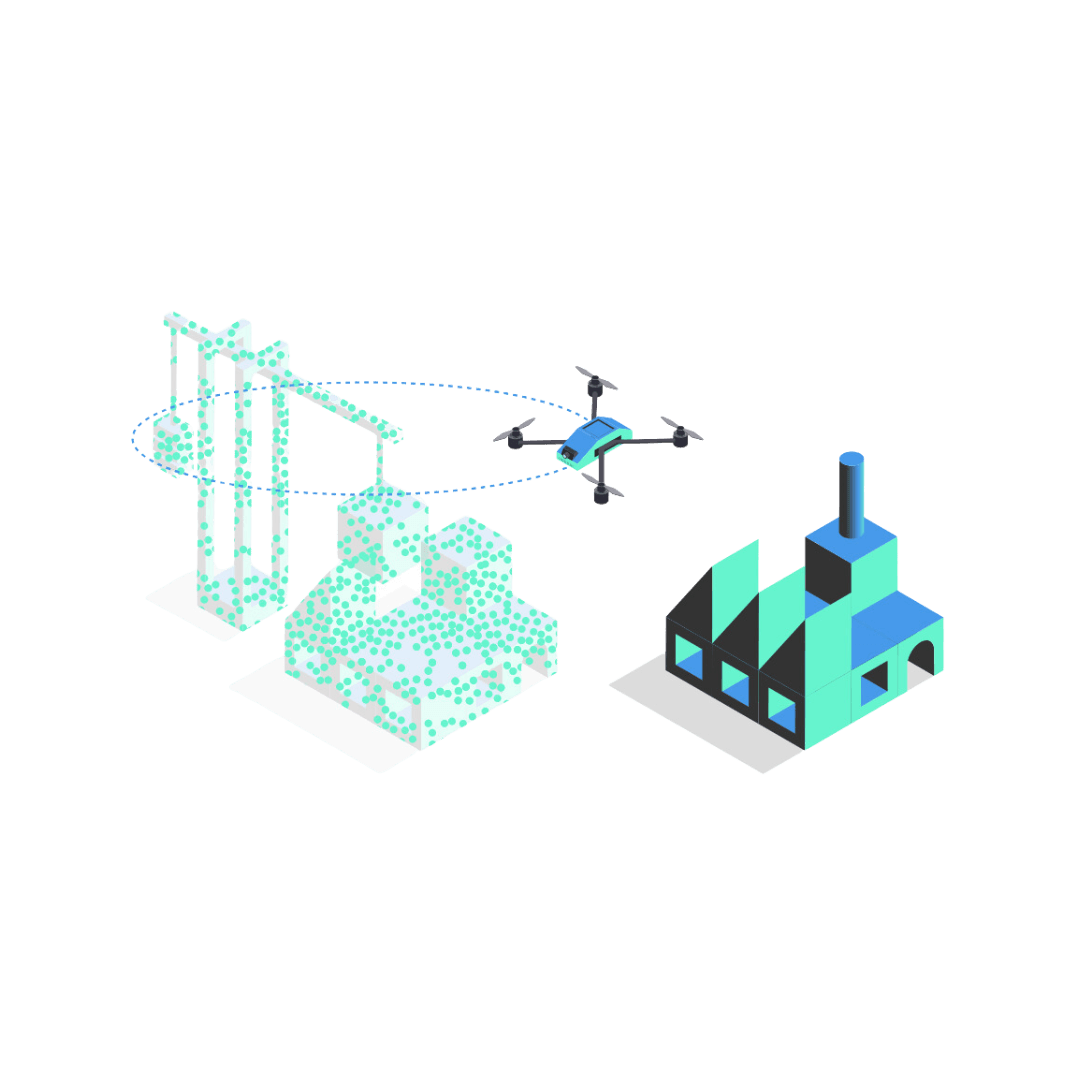

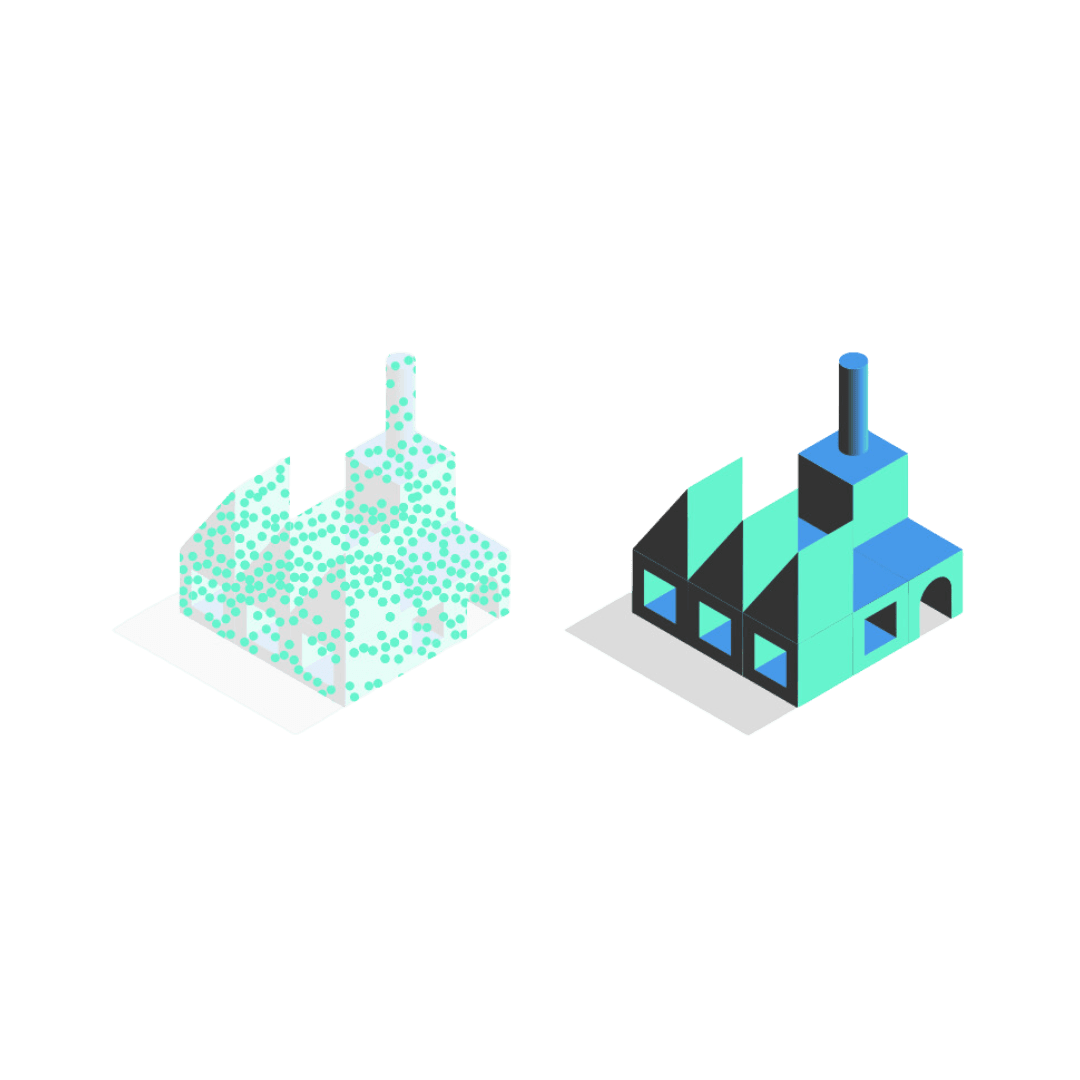

Scan existing facility by drone using camera or LiDAR to get accurate digital replica or use digital twin from Progress Monitoring

Build the Digital Twin or your facility using 3D asset library

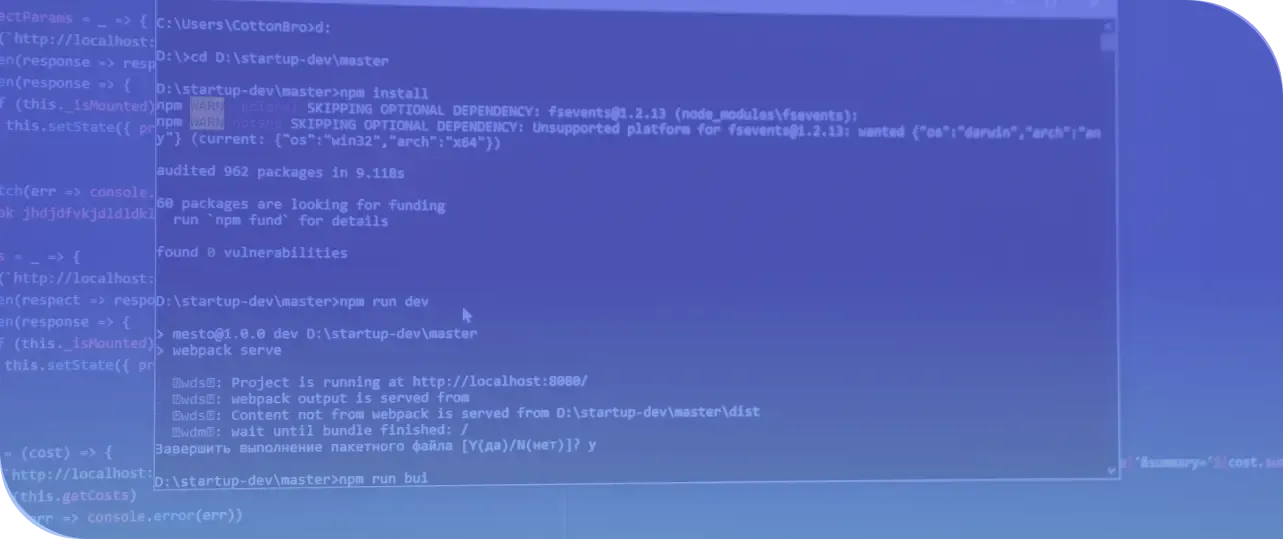

Various Data Sources

Configure the data hierarchy and dashboard

Monitoring and prediction

ProcessHub Server

Cloud or on premise

Store and Clean

Learn & Analyze

Build & connect

AI/ML Algorithms

Alert &

Predict

Connect assets by pipes

Add widgets with data to assets for monitoring

Monitor the parameters of the asset with historical data and AI prediction, configure alarm list and attach documents

Metaverse experience

ProcessHub Solutions

Advanced Machine And AI-Driven Suggestions

Applies machine learning and AI to recommend optimal actions based on data insights

Rules-Based Logic For Sensor Data

Applies predefined rules to analyze sensor inputs and trigger automatic responses

Real-Time Analytics And Sensing Insights

Provides instant analysis of live sensor data to assess and enhance asset reliability

Actionable Insights And Decision Support

Delivers clear, data-driven insights to guide strategic and operational decisions.

Integration Capabilities

ProcessHub is designed with seamless integration capabilities, enabling it to connect effortlessly with any existing systems, including IoT platforms, SCADA, ERP, CMMS, and custom enterprise solutions, ensuring a unified and efficient workflow across all operations.

Flexible Integration

Pooling

Regularly retrieving data

Web Hooks

Instant event updates

PH Power Connectivity

Scada System

ASP System

ERP System

- OSI PI System

- Excel

- Data Center Expert

- Hexagon

- Aveva

ProcessHub and the Energy Industry

ProcessHub's Digital Twin technology provides value to all areas of Oil & Gas and Petrochemical value chain starting from upstream, mid-Stream and downstream.

Energy Subsectors

Oil & Gas

Renewable

Electricity

Atomic

Sector Components

Upstream

Exploration & Production

In the Upstream area and due majority of the assets such as reservoirs, wells and gathering systems are in remote and difficult access areas, ProcessHub offers real time data and operational knowledge tailored to the needs of decision-makers. This reduces presence with health and safety benefits as well as significant cost savings. The added value in terms of security and environmental monitoring contributes to both cost reduction and transparency in reporting.

Midstream

Trading

Midstream that includes pipelines, storage capability and transport will provide accurate information of capacity usage and predict flow in capacity. Again, ease of access of real time remote data will contribute to better decisions that save both cost and safe interventions.

Downstream

Trading

Downstream facilities including petrochemicals, will benefit from preventative operations and maintenance at asset level, improvement of production at product levels due to changes in specifications or feed, at service levels provide better quality of service and manage service teams more effectively and at an organization level it will facilitate training and change management needs.

Metaverse Experience

From Digital Twins to Metaverse

Introducing the future of digital twin technology - ProcessHub extends beyond just mirroring reality and transforms industries by fully immersing customers in the metaverse through the integration of augmented reality, virtual reality, and mixed reality technologies. Imagine being able to walk through a digital replica of an Oil and Gas plant before it's even built or virtually test a factory and commission it from the comfort of your desk. ProcessHub allows for limitless possibilities in design, simulation, and training, revolutionizing the way businesses operate. Not only does it offer a more efficient and cost-effective solution, but it also allows for greater collaboration and innovation. Experience the metaverse like never before with our cutting-edge digital twin product - ProcessHub.